In modern low voltage (LV) electrical installations, maintaining power quality and ensuring reliability are critical, especially in sensitive environments like offices, hospitals, and industries. Backup power systems and power conditioning equipment play a vital role in achieving this.

Let’s explore where each type of equipment fits into the overall architecture, including the placement of LT Panels (MDBs), Distribution Boards (SDBs and Final DBs), and control devices like MCBs, Isolators, Switches, and Sockets.

Service Entrance: The Starting Point

The journey begins at the service entrance, where power from the utility or a local transformer enters the facility.

- Utility Meter / Transformer →

- Main Incoming Breaker →

- MDB (Main Distribution Board / LT Panel)

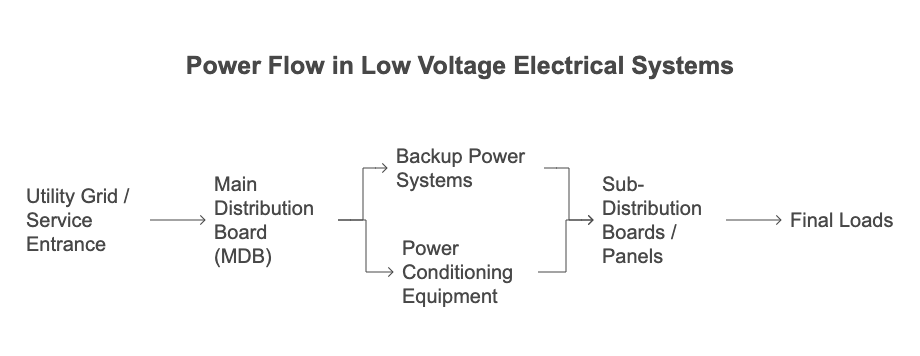

From the service entrance, at a high level, the power flow in a typical LV system can be understood as:

- Service Entrance

- Main Distribution Board (MDB)

- Backup Power Systems & Power Conditioning Equipment

- Sub-Distribution Boards / Panelboards

- Final Electrical Loads (Lighting, Fans, Computers, Machinery, etc.)

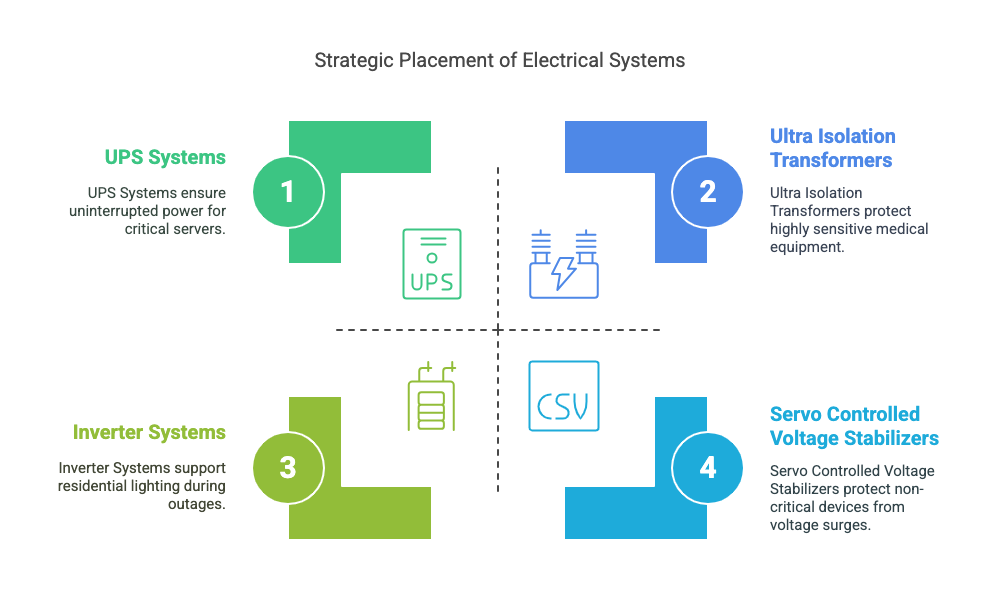

Backup power and conditioning equipment are strategically placed between the MDB and the sensitive or critical loads to ensure continuous and high-quality power delivery.

Main Distribution Board (MDB or LT Panel)

The MDB is the heart of the building’s electrical system. It receives the incoming power and distributes it across various sections of the facility.

Equipment Connected at MDB:

- Diesel Generator (D.G.) Sets: Provide backup during grid failures.

- UPS Systems: Ensure no-break power for critical loads.

- Inverter Systems: Used mainly for smaller backup power needs.

- Servo Controlled Voltage Stabilizers (SCVS): Regulate voltage fluctuations to protect equipment.

- Isolation Transformers: Provide galvanic isolation and noise filtering.

- Ultra Isolation Transformers: Offer higher degree of noise attenuation.

- K-Rated Isolation Transformers: Handle harmonic-rich loads like IT equipment.

Components within MDB:

- Incoming Air Circuit Breaker (ACB) or MCCB

- Outgoing MCCBs/MCBs feeding Sub-Distribution Boards (SDBs)

- Energy meters, Protection Relays, Busbars

Sub-Distribution Boards (SDBs)

Power from the MDB flows into Sub-Distribution Boards, strategically located closer to load zones like floors or large departments.

Role of SDBs:

- Further distribute power to different parts of the building.

- Supply medium-sized loads like HVAC systems, heavy machinery, or clusters of final DBs.

Components within SDBs:

- Incoming MCCBs/MCBs

- Outgoing MCBs or Isolators to feed Final Distribution Boards (DBs)

Final Distribution Boards (Final DBs)

Final DBs serve specific rooms, offices, machine clusters, or operational zones.

Role of Final DBs:

- Deliver power to end-use devices and appliances such as lights, fans, sockets, and localized machinery.

Controls and Protections at Final DBs:

- MCBs (Miniature Circuit Breakers): Protect individual circuits from overloads and short circuits.

- Isolators: Allow safe disconnection for maintenance or emergencies.

- Switches and Sockets: Provide user-level control and access to electrical power.

Backup and Conditioning Equipment Integration

- Diesel Generator Sets typically integrate into the MDB, either automatically or manually switching during outages.

- UPS Systems can feed critical Final DBs through a separate Emergency DB to ensure uninterrupted power.

- Inverter Systems generally support lighter critical loads, often routed through specific Final DBs.

- Servo Controlled Voltage Stabilizers (SCVS), Isolation Transformers, Ultra Isolation Transformers, and K-Rated Transformers are inserted at appropriate stages depending on the load sensitivity and distribution requirements.

For example:

- A server room may have a K-rated transformer and UPS power routed through its dedicated Final DB.

- A CNC machine floor might receive power through an SCVS and isolation transformer to ensure stable voltage and reduce noise.

Key Backup Power Systems

1. Diesel Generator (D.G.) Sets:

D.G. sets provide backup power in case of a utility failure. Typically, the generator is connected to the system via an automatic transfer switch (ATS) or manual changeover panel. The generator kicks in after a brief delay when grid power fails, ensuring essential loads continue operating.

Placement: After MDB, feeding selected critical circuits.

2. UPS (Uninterruptible Power Supply) Systems:

UPS systems are essential for instantaneous backup power, especially for sensitive equipment like computers, servers, and hospital machines. Unlike generators, UPS systems provide zero transfer time by instantly switching to battery power.

Placement: Between the MDB and critical loads that require no interruption.

3. Inverter Systems:

Inverters are typically used for lighter backup loads such as residential lighting and fans. They convert stored DC battery power to AC for use during outages.

Placement: Near or integrated into sub-panels feeding non-critical but necessary loads.

Key Power Conditioning Equipment

4. Servo Controlled Voltage Stabilizers (SCVS):

SCVS units regulate incoming voltage fluctuations to ensure that the output voltage stays within safe, predefined limits. This is important to protect sensitive devices from voltage surges and sags.

Placement: Ahead of sensitive panels or directly feeding critical equipment.

5. Isolation Transformers:

Isolation transformers physically isolate the primary power source from the secondary power line, helping in reducing electrical noise and providing an additional layer of protection.

Placement: Close to critical loads to maximize noise rejection.

6. Ultra Isolation Transformers:

An enhanced version of standard isolation transformers, ultra isolation transformers are designed to provide higher levels of noise attenuation and better protection against high-frequency disturbances.

Placement: Feeding highly sensitive electronic loads such as medical equipment or precision instruments.

7. K-rated Isolation Transformers:

K-rated transformers are designed to handle high harmonic content without overheating. They are commonly used in buildings with a significant amount of non-linear loads (like servers, UPS systems, VFDs).

Placement: Between power distribution and high-harmonic-generating equipment.

Conclusion

In summary, backup power systems like D.G. sets, UPS, and inverters ensure that critical operations continue even during power failures. Power conditioning equipment like SCVS, isolation transformers, ultra isolation transformers, and k-rated transformers protect sensitive loads from voltage fluctuations, electrical noise, and harmonics.

A well-designed LV electrical system incorporates these elements strategically to provide a robust, resilient, and clean power infrastructure, ensuring both operational continuity and protection of valuable assets.

If you would like to discuss your facility’s specific needs for backup power and power conditioning solutions, feel free to contact our team at Ohm Electricals — we are here to help!